Recycled lithium-ion batteries work as well as those made from new materials. (Photo: WEERAPAT/DepositPhotos)

Electric cars play an important role in reducing the emissions which drive global climate change, given how many people drive automobiles. As opposed to gas-guzzling cars, electric cars store their power in rechargeable lithium-ion batteries. However, even these batteries have finite lifespans. When the batteries or the car they supply are junked, lithium-ion batteries present a significant problem of disposal. Meanwhile, the creation of new batteries for new cars involves the dangerous mining of metals and significant energy expenditure. Luckily, a new study published in Joule explains that recycling the conductive cathodes of lithium-ion can create more sustainable batteries which are as good as “virgin” cells.

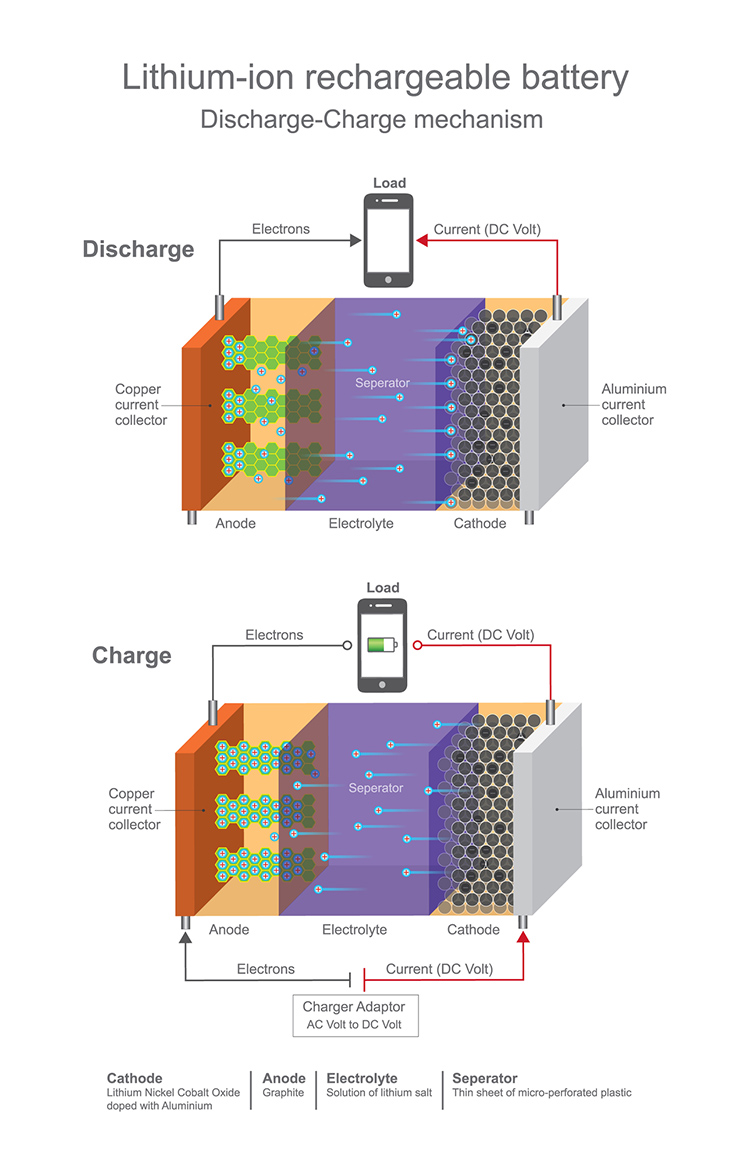

Yan Wang, a professor at Worcester Polytechnic Institute, worked with a team of scientists to investigate the possibilities of recycling the valuable metals inside lithium-ion batteries. Wang explained to IEEE Spectrum, “Battery companies still hesitate to use recycled material in their batteries.” However, are these recycled materials actually sub-par? To find out, the team tested recycled NMC111 cathodes from batteries. A cathode is the part of the battery which acquires the electrons (the current) from the circuit and reduces it for transmission through a chemical reaction.

The NMC111 cathode is composed of the valuable elements nickel, manganese, and cobalt. Battery Resourcers—a start-up co-founded by Wang—has developed a patented technique to recycle these elements into cathode material. Unlike other processes, the end product is ready to use. The study found that the recycled material had a porous structure which retained the same energy density as new material but also had an over-50% longer life. This conductivity enables the movement of lithium ions and suggests that recycled batteries may even outperform virgin cells. Although not tested in cars, the cells were tested with similar energy requirements.

The recycling of lithium ion batteries is complex. They can be burned or dissolved. Battery Resourcers' patented technique strips away the outer packaging for recycling and sale separately. The cathode material is the most valuable part of the battery. It is dissolved, filtered, and mixed to form new cathode powders. The start-up is already selling these powders to car manufacturers for the creation of new cathodes in new batteries. This saves some of the energy involved in mining new materials, as well as the human and ecological costs of a troubling industry. If electric cars are the future, battery recycling must be as well.

Tests show lithium-ion batteries made from recycled materials perform just as well as those made with new materials.

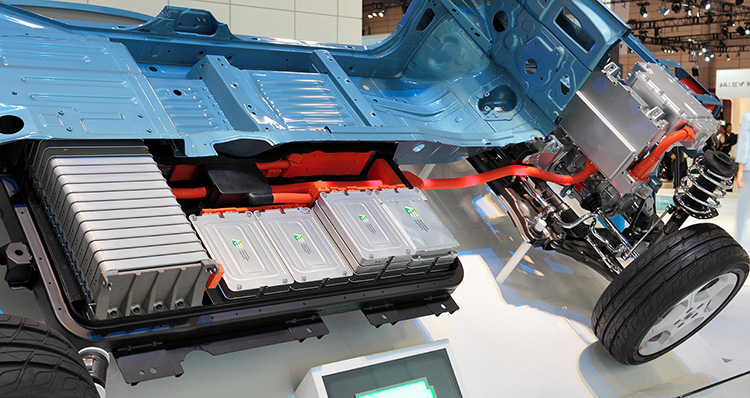

The batteries of the Nissan Leaf as displayed in 2009. (Photo: Tennen-Gas via Wikimedia Commons, CC BY-SA 3.0)

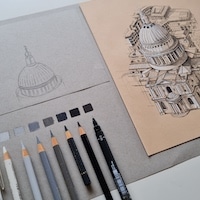

Lithium-ion battery cathodes must be recycled to avoid the problems associated with the proliferation of electronic vehicles.

Lithium ion rechargeable battery diagram. (Photo: PATTARWIT/DepositPhotos)

h/t: [IEEE Spectrum]

Related Articles:

Gen Z Is Devoting Their Budding Careers To Fighting the Climate Crisis

This Sleek Wind Turbine Wall Lets You Harness Enough Energy to Power Your Home

The Ocean Cleanup Successfully Hauls 20,000 Pounds of Plastic From the Pacific Ocean

Spain Bans Plastic Wraps for Fruit and Vegetables in Step to Reduce Waste