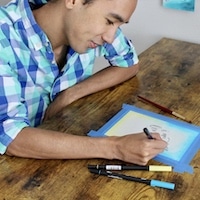

Photo: Stock Photos from marekuliasz/Shutterstock

Printmaking has helped change the world. The ability to reproduce text and images allowed information and ideas to quickly and easily spread throughout society, making knowledge not just a marker of the rich or well connected.

It was the invention of the printing press, refined in the 15th century, that facilitated this phenomenon. But what technique was used to put ink to paper? Letterpress printing was the means by which letterforms were transferred onto paper, and the approach remains relevant today—even in the age of digital printing.

What is letterpress printing?

The name letterpress gives us a clue about how it works. It’s a type of relief printing that makes copies by impressing an inked, raised surface onto paper.

The moveable type—which can be wood or metal—is often composed by hand and locks into the “bed” of the press. Ink is then applied; and after, the paper is rolled over the moveable type at high pressure. The result is printing that leaves a heavy impression on the paper. You can feel it when you run your hand over it.

Industrialization of Letterpress Printing

Photo: Stock Photos from jusch/Shutterstock

The industrialization of letterpress printing is what allowed these massive changes to how information was shared. By mechanizing the printing press, it helped to minimize the amount of work needed from humans and it also allowed for the production of printed copies at a faster rate.

An automated press has ink that is applied to a plate, which then has rollers that go over its surface and are loaded with ink. After, the rollers pass over the bed containing type and images. To print onto a surface, the paper is attached to a hinged platen and then pressed onto the plate. Once done, the operator removes the paper from the platen and replaces it with a fresh sheet, starting the process all over again.

Photo: Stock Photos from jusch/Shutterstock

One major advancement in letterpress printing is the rotary press. This type of printing press is used for high speed (and high volume) work—think newspaper production. Essentially, it prints on a paper that is placed between two cylinders turning in opposite directions. One of the rotating drums contains pictures and text that curve around the cylinder, while the other is an “impression cylinder” that works to press the paper to the inked plates. Paper is continuously fed through the drums via the machine which allows for rapid printing. (Modern rotary presses can move at a speed of nearly 20 miles per hour.)

Process of Letterpress Printing

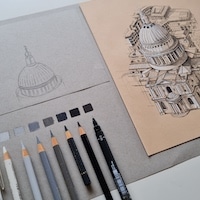

Photo: Stock Photos from Ashihara/Shutterstock

Printmaking is a very process-oriented art, and letterpress is no exception. There are three stages that go on during letterpress printing to create a single print.

Composition

Composition, also called typesetting, is the initial stage in which the person responsible for placing the text puts it on a type galley. This is a meticulous process because each form must be placed letter after letter, line after line.

This traditional method was the only available approach until the 1980s when a new manufacturing process was created—the photopolymer plate. This light-sensitive plate has a surface that is “cured” when it is exposed to UV light. An image (or type) is printed on a negative film that is then put on an unexposed plate. After it is exposed to light, the negative film is removed and the plate is cleaned with water, leaving the design visible. It is then exposed to UV light again to give it stability.

Photopolymer plates give the designer a lot more possibilities as they aren’t limited by having to handset the type. These designs can first be digitally produced.

Imposition

Imposition occurs after the type has been handset and is ready to be used on the press. Often, this involves arranging pages of type with regards to how they’ll be printed, cut, and bound (into a book, for instance).

Printing

At this stage, the ink is applied to the type (or image) and then run through the press to create the intended output of the design. How this works depends on the type of press used.

Letterpress’ Popularity Wanes and Eventually Resurges

View this post on Instagram

Like many analog activities, the popularity of letterpress waned during the 1970s thanks to the rise of computers. This caused many commercial printing businesses to shutter their doors during the following twenty years, and they sold their presses at a discounted cost to artisans and individuals.

Artisans helped to ensure that letterpress was never forgotten. It even saw a revival in the 1990s thanks to the craft queen Martha Stewart—Martha Stewart Weddings magazine showcased invitations printed by hand and highlighted the technique as a way to add an exquisite touch to printed matter.

Today, letterpress printing remains a way to infuse a handcrafted touch in a world seemingly ruled by screens. Look for it on greeting cards, invitations, and more, and you'll realize how relevant it still is.

Related Articles:

40+ Most Creative Business Cards That Are Sure to Get Noticed

How Alphonse Mucha’s Sinuous Art Nouveau Posters Elevated Printmaking as an Art Form

The Unique History and Exquisite Aesthetic of Japan’s Ethereal Woodblock Prints