You might have heard about engineers and artists working for years to create the world’s blackest black, but what about the other end of the spectrum? In October 2020, a team at Purdue University’s School of Mechanical Engineering created the world’s whitest white paint, capable of reflecting 95.5% of all light that hits it. Now, that team has outdone themselves with a new lightweight paint that’s somehow even whiter than the last, with some incredible application potentials.

As the Purdue team, led by Professor of Mechanical Engineering Xiulun Ruan, set out to create an ultra-white paint, they weren’t aiming to win awards or land on late-night television shows. “When we started this project about seven years ago,” Ruan says, “we had saving energy and fighting climate change in mind.” In collaboration with his graduate students, Ruan set out to create a paint that could reflect sunlight better than any other paint. But when they beat out their previous 2020 white paint by inventing a paint in April 2021 with an incredible reflectivity of 98.1%, the world took notice. The barium sulfate substance, used in photo paper and cosmetics, landed in the 2022 Guinness World Records and on The Late Show with Stephen Colbert, attracting even more attention.

When covered in the team’s April 2021 formula, an outdoor surface could be cooled more than 4.5°C (8.1°F) below the temperature that surrounds it, without using any energy. Covering a roof would result in a cooling power of 10 kilowatts, which Ruan clarifies is “more powerful than the air conditioners used by most houses.” Not only is the paint more powerful than ACs, it also ensures heat doesn’t stay trapped in Earth’s atmosphere. Because it’s so reflective, it sends the heat back into space where it travels indefinitely at the speed of light. Thus, ensuring less atmospheric heat contributes to global warming and ensuring the building doesn’t heat up in the first place.

The only issue with this incredible feat was the paint’s thickness. “To achieve this level of radiative cooling below the ambient temperature, we had to apply a layer of paint at least 400 microns thick,” Ruan revealed. While .4 millimeters doesn’t seem like a lot, the experience mechanical engineer explains, “in applications that have precise size and weight requirements, the paint needs to be thinner and lighter.”

As a result of how effective this paint is, Ruan states: “I’ve been contacted by everyone from spacecraft manufacturers to architects to companies that make clothes and shoes. stated. They mostly had two questions: Where can I buy it, and can you make it thinner?” So, his team set out to experiment with other materials to surpass their formula. They struck (white) gold in hexagonal boron nitride, a substance mainly used in lubricants.

Their newest boron nitride formula performs nearly identical in reflectivity (97.9%) to their previous formula, while only being a fraction of the thickness and weight. It only needs to be applied 150 microns (.15 millimeters) in thickness, and because it is so porous, it’s 80% lighter than its predecessor. “Now this paint has the potential to cool the exteriors of airplanes, cars, or trains,” explains Ruan. “An airplane sitting on the tarmac on a hot summer day won’t have to run its air conditioning as hard to cool the inside, saving large amounts of energy. Spacecraft also have to be as light as possible, and this paint can be a part of that.”

The team is working on commercializing the paint so that we can see these real world applications actually happen. But in the meantime, it’s pretty incredible to think about what impact the pigment could have on the environment. Ruan emphasizes, “Using this paint will help cool surfaces and greatly reduce the need for air conditioning. This not only saves money, but it reduces energy usage, which in turn reduces greenhouse gas emissions. And unlike other cooling methods, this paint radiates all the heat into deep space, which also directly cools down our planet. It’s pretty amazing that a paint can do all that.”

In October 2020, a team at Purdue University’s School of Mechanical Engineering created the world’s whitest white paint, capable of reflecting 95.5% of all light that hits it.

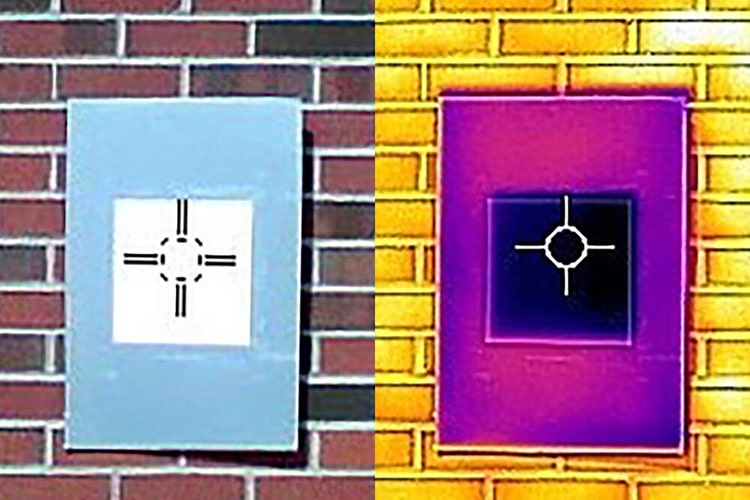

Purdue researchers Xiulin Ruan and Joseph Peoples use an infrared camera to compare the cooling performance of white paint samples on a rooftop. (Photo: Jared Pike/Purdue University)

With the aim to combat global warming, the team experimented with ways to reflect even more light. And in April 2021, they were able to invent a new paint, made of barium sulfate, a material found in photo paper and cosmetics. Its reflectivity was 98.1%.

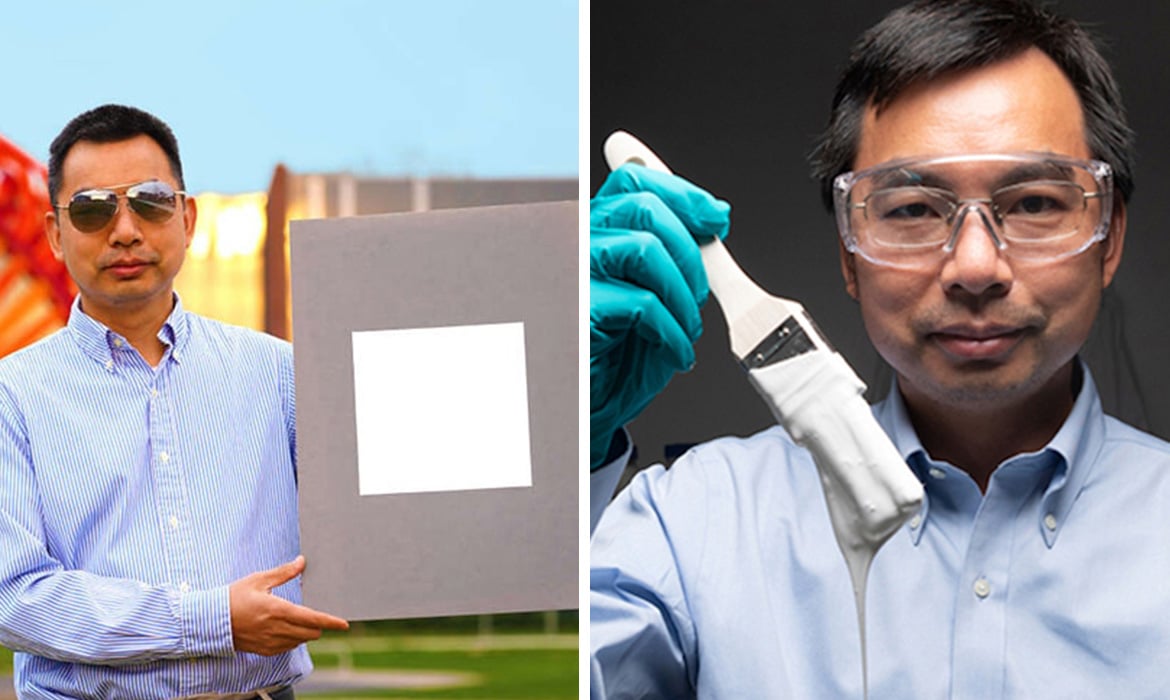

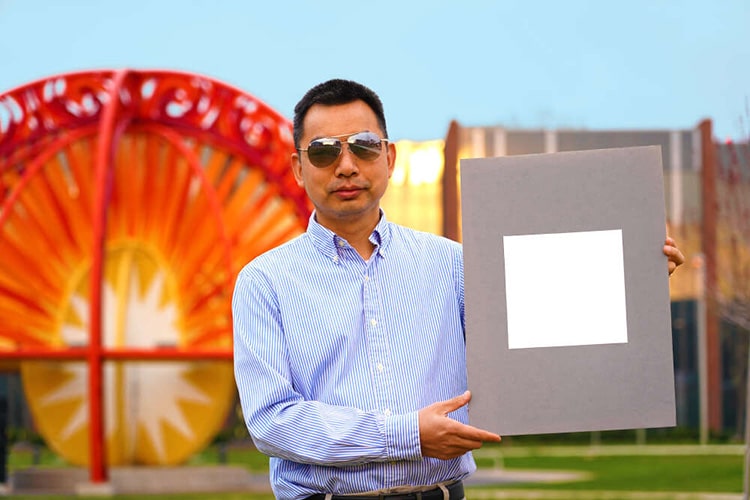

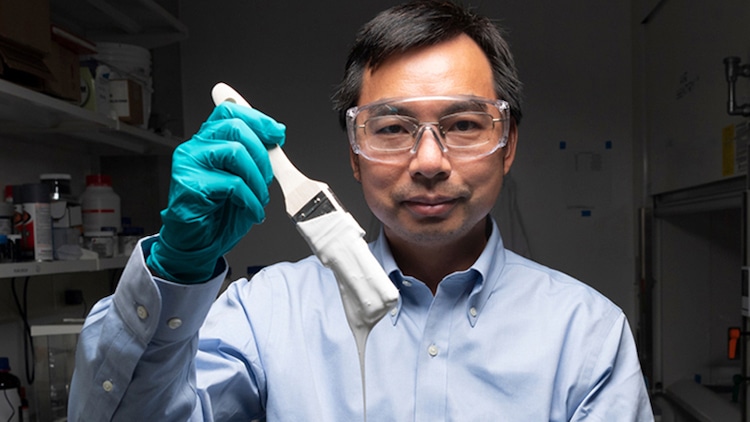

Prof Xiulin Ruan with a sample of the whitest paint yet developed. (Photo: Jared Pike/Purdue University)

An outdoor surface covered in their new formula could be cooled more than 4.5°C (40.1°F) below the temperature that surrounds it, without using any energy. A roof covered in the paint would result in a cooling power of 10 kilowatts, which is more powerful than air conditioners in most homes.

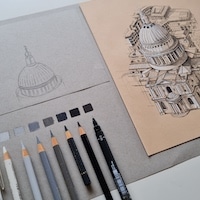

Infrared images showing how the ultrawhite paint actually has a cooling effect. The purple is ambient temperature, the black represents the cooler painted swatch. (Photo: Joseph Peoples/Purdue University)

The only issue this new formula had was that it was too thick to be applied to anything other than stationary structures, like large buildings. So the team set out to experiment with more materials. In October 2022, the team published their newest formula, comprised of hexagonal boron nitride, a substance mainly used in lubricants.

Professor Xiulin Ruan (Photo: John Underwood/Purdue University)

The new paint performs nearly identical in reflectivity (97.9%) to their previous formula, while only being a fraction of the thickness and weight, making it perfect for a wide range of applications. The Perdue team has been contacted by spacecraft manufacturers, clothing companies, and architects, and is working on commercializing their paint.

The new formula is 2.7 times thinner than the previous one. (Photo: Andrea Felicelli/Purdue University)

Soon, you could see the whitest white on cars, airplanes, trains, and buildings everywhere, reducing the need for air conditioning—which saves you from a big bill, wastes less energy, and reduces greenhouse gas emissions.

Photo: dell640/Depositphotos

Purdue University's School of Mechanical Engineering: Website | Facebook | YouTube

h/t: [Smithsonian Magazine]

Related Articles:

Researchers Create “UltraWhite” Paint That Reflects Light and Cools Buildings

Whitest Paint Ever Developed Could Reflect Enough Light to Slow Global Warming

MIT Engineers Discover World’s Blackest Black, Taking Title from Vantablack

Artist Stuart Semple Just Invented the World’s Blackest Black Ink Called ‘Blink’