You can create DIY enamel pins!

You don’t need to know how to inlay enamel to create your own pins—you just need to have a great design in mind. And at less than a dollar a pin to produce, they can offer a great way to advertise your illustration or design sensibilities.

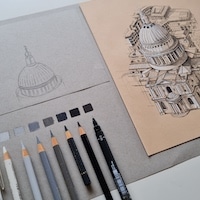

When having your own badges produced, there are a couple of options for finishing: hard enamel and soft enamel. So, what’s the difference?

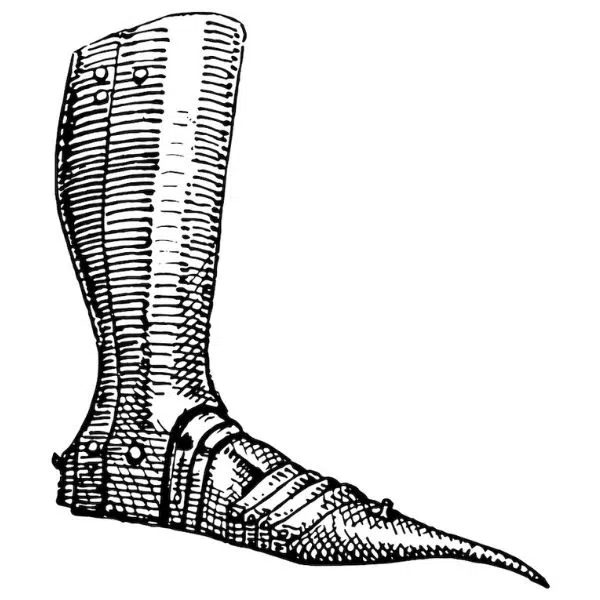

Soft enamel pins have recessed enamel, meaning that when you run your finger across its surface, it will feel “bumpy.” This is because the pin’s image is first stamped on the metal and cut to size. It’s then plated in metal such as gold or nickel. Afterward, enamel is added to the recessed areas and baked.

Hard enamel pins look glossy and feel smooth. The enamel is added before the plating, and it’s polished to the same level as the stamped metal lines. Because of this process, it’s a tricker to achieve fine details.

Once you've got your design in mind, places like Made By Cooper will produce them for you. Be sure to check out the individual specifications required, as they vary from site to site.

Related Articles:

20+ Pieces of Modern Map Art Putting a Contemporary Spin on Cartography

Designers Use NASA Elevation Mapping to Precision Craft Mountainous Landscape Jewelry